Air adjustment on Beckett oil burners is a critical aspect of maintaining optimal performance, efficiency, and safety. This comprehensive guide delves into the principles, techniques, and troubleshooting steps involved in achieving the correct air-to-fuel ratio for your Beckett oil burner, ensuring optimal combustion and minimizing potential hazards.

Proper air adjustment is essential for ensuring complete combustion, preventing soot formation, and maximizing heat output. By understanding the combustion process and the role of air in it, you can optimize your burner’s performance and extend its lifespan.

Air Adjustment Principles

Proper air adjustment is crucial for optimal oil burner performance. It ensures complete combustion, minimizing emissions and maximizing efficiency.

During combustion, fuel reacts with oxygen to produce heat and exhaust gases. The air-to-fuel ratio must be precisely controlled to achieve complete combustion. Too little air results in incomplete combustion, producing soot and smoke. Too much air cools the flame, reducing efficiency.

Air Damper Settings: Air Adjustment On Beckett Oil Burner

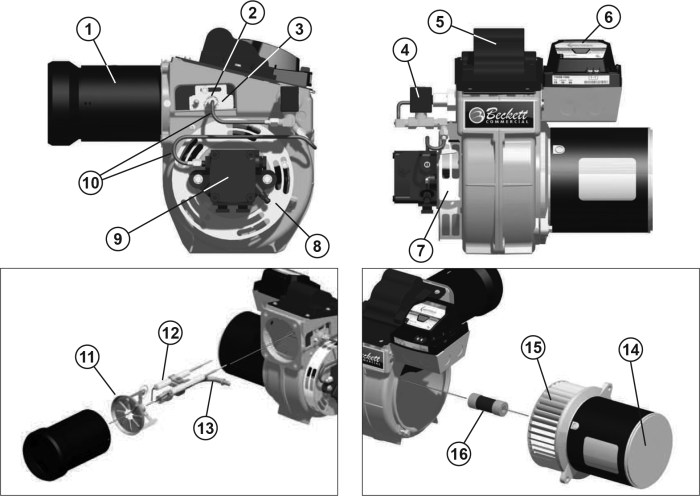

The air damper regulates the amount of air entering the combustion chamber. It is typically located on the burner housing.

To adjust the air damper, use a screwdriver to turn the adjusting screw. Turning the screw clockwise reduces air flow, while turning it counterclockwise increases air flow.

Troubleshooting common air damper issues:

| Issue | Cause | Solution |

|---|---|---|

| Soot formation | Insufficient air | Increase air flow by turning the adjusting screw counterclockwise |

| Weak flame | Excessive air | Decrease air flow by turning the adjusting screw clockwise |

Smoke Analysis and Adjustments

Smoke analysis is a method to assess air adjustment settings. A smoke tester is used to measure the opacity of the exhaust gases.

To conduct a smoke test:

- Run the burner at the desired operating conditions.

- Insert the smoke tester probe into the exhaust stack.

- Record the smoke opacity reading.

The ideal smoke opacity varies depending on the burner model and fuel type. Adjust the air damper to achieve the recommended smoke opacity.

Combustion Efficiency Optimization

Combustion efficiency measures the percentage of fuel energy that is converted into heat. Proper air adjustment contributes to improved combustion efficiency by ensuring complete combustion.

Best practices for maintaining optimal combustion efficiency:

- Regularly clean the burner and nozzle.

- Ensure the correct fuel pressure.

- Adjust the air damper according to the manufacturer’s recommendations.

Safety Considerations

Improper air adjustment can lead to safety hazards.

Carbon monoxide poisoning: Insufficient air can result in incomplete combustion, producing carbon monoxide, a colorless, odorless gas that is toxic to humans.

Fire: Excessive air can cool the flame, leading to incomplete combustion and the accumulation of unburned fuel. This can increase the risk of fire.

Safe air adjustment procedures:

- Always follow the manufacturer’s instructions.

- Use a qualified technician to perform air adjustments.

- Ensure adequate ventilation in the boiler room.

Helpful Answers

What is the purpose of the air damper on a Beckett oil burner?

The air damper controls the amount of air entering the combustion chamber, regulating the air-to-fuel ratio and optimizing combustion efficiency.

How can I troubleshoot common air adjustment issues on a Beckett oil burner?

Refer to the troubleshooting table in the guide for step-by-step instructions on resolving common air adjustment problems, including causes and solutions.

Why is proper air adjustment important for safety?

Improper air adjustment can lead to incomplete combustion, producing harmful carbon monoxide and increasing the risk of fire.